E-cigarette ceramic core atomisation principle and material advantage analysis

February 21, 2024

E-cigarette ceramic core atomisation principle and material advantage analysis

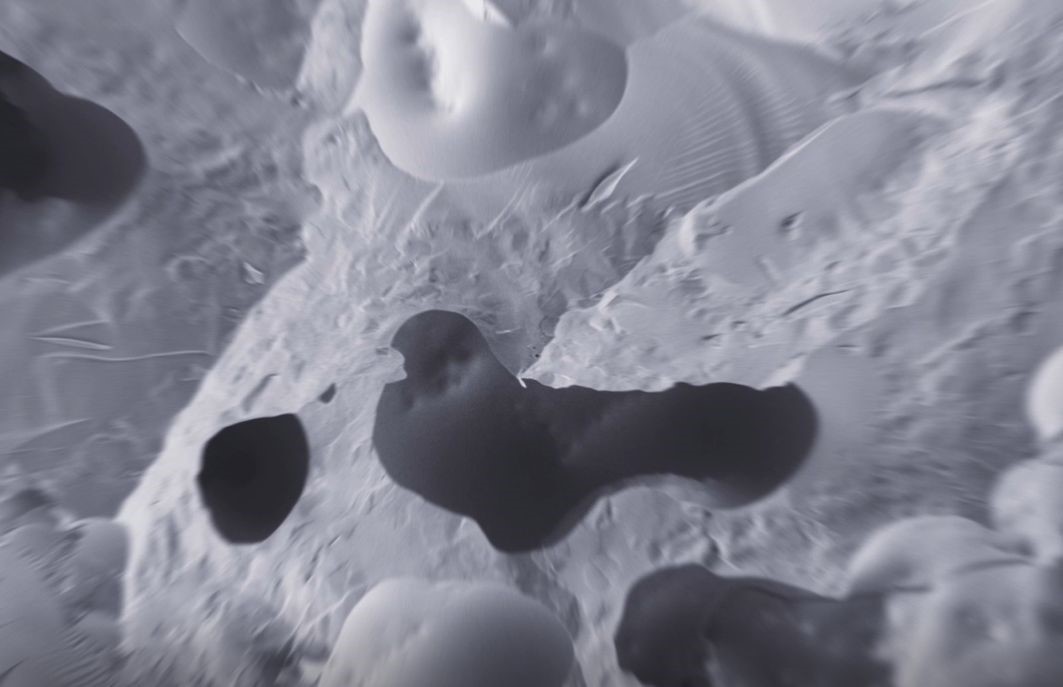

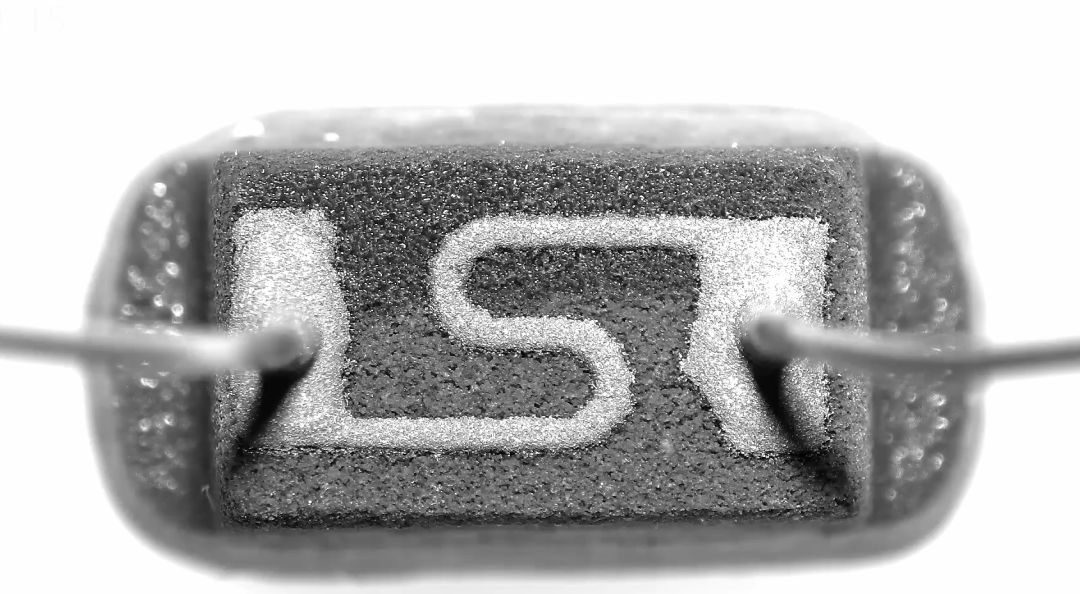

As the "heart" of the atomisation technology, the core determines the atomisation effect and experience. Nowadays, ceramics in the field of atomisation technology burst of vitality, become the standard of high-quality atomiser. So, what is the principle of ceramic fogging? What are the advantages of ceramic material? First, why use ceramic as material? Ceramic is not the only material applied to the atomising core in electronic atomisers. Materials such as fibre rope, organic cotton, non-woven fabrics, etc., have been applied to make atomizing cores. The ceramic applied in the atomising core is not the same as the common ceramic we see on the dining table, it is a special kind of "porous ceramic".  This is a photo of the ceramic after magnifying it tens of thousands of times. In a ceramic core, there are about hundreds of millions of micro and nano pores like this one. And the combination of this small piece of ceramic material and a metal membrane, which is littered with micropores, forms the core component of an electronic atomiser.

This is a photo of the ceramic after magnifying it tens of thousands of times. In a ceramic core, there are about hundreds of millions of micro and nano pores like this one. And the combination of this small piece of ceramic material and a metal membrane, which is littered with micropores, forms the core component of an electronic atomiser.  Ceramic atomiser core main components derived from nature, after high temperature sintering, the internal formation of many tiny micropores, the average pore size equivalent to one-fifth of a hair strand.

Ceramic atomiser core main components derived from nature, after high temperature sintering, the internal formation of many tiny micropores, the average pore size equivalent to one-fifth of a hair strand.  These tiny microporous holes are the key to the ceramic atomiser core's stable liquid-conducting and liquid-locking functions. Due to surface tension and capillary action, the liquid can penetrate evenly into the atomiser core and adsorb on the surface of the core.

These tiny microporous holes are the key to the ceramic atomiser core's stable liquid-conducting and liquid-locking functions. Due to surface tension and capillary action, the liquid can penetrate evenly into the atomiser core and adsorb on the surface of the core.  Similar to activated carbon, porous ceramic materials have strong adsorption properties and at the same time very good biocompatibility properties. This is one of the key factors in choosing ceramics as a carrier. Similar materials have many applications in daily life, such as filter cartridges for water purifiers, refrigerator deodorants, face masks, toothpaste and other daily necessities. Second, what are the advantages of ceramic atomising core? Compared with the atomising core composed of other materials, such as heating wire and fibre rope, heating wire and organic cotton, the ceramic atomising core is characterised by a faster rise in temperature, better temperature uniformity and more precise control of the temperature range during the heating process. This can reduce the production of aldehydes and ketones in the process of use to a greater extent, thus ensuring the safety of the use process.

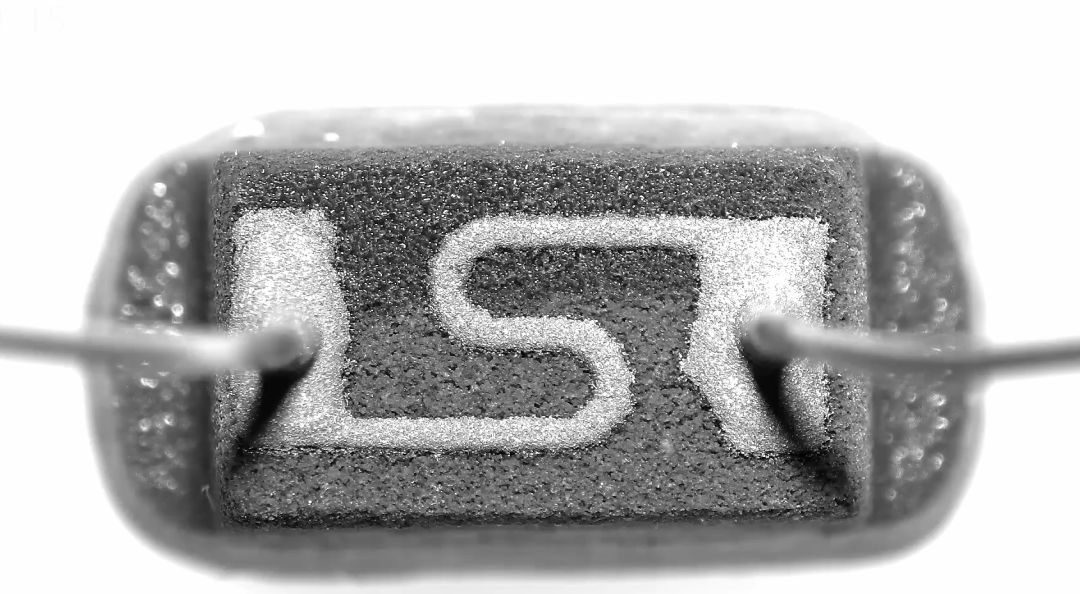

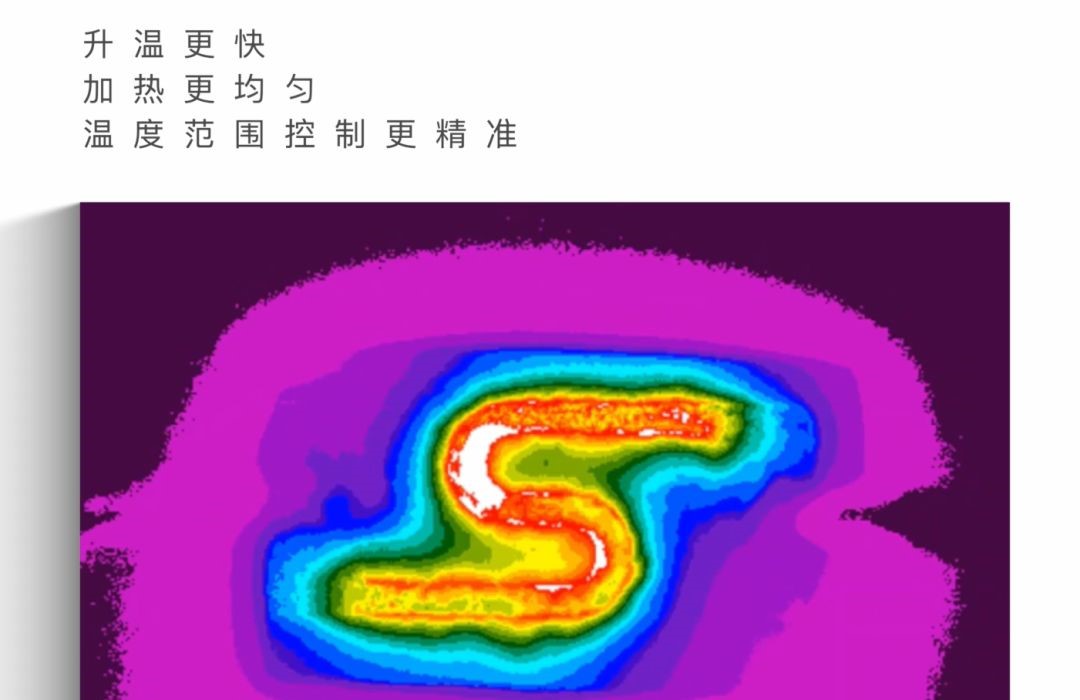

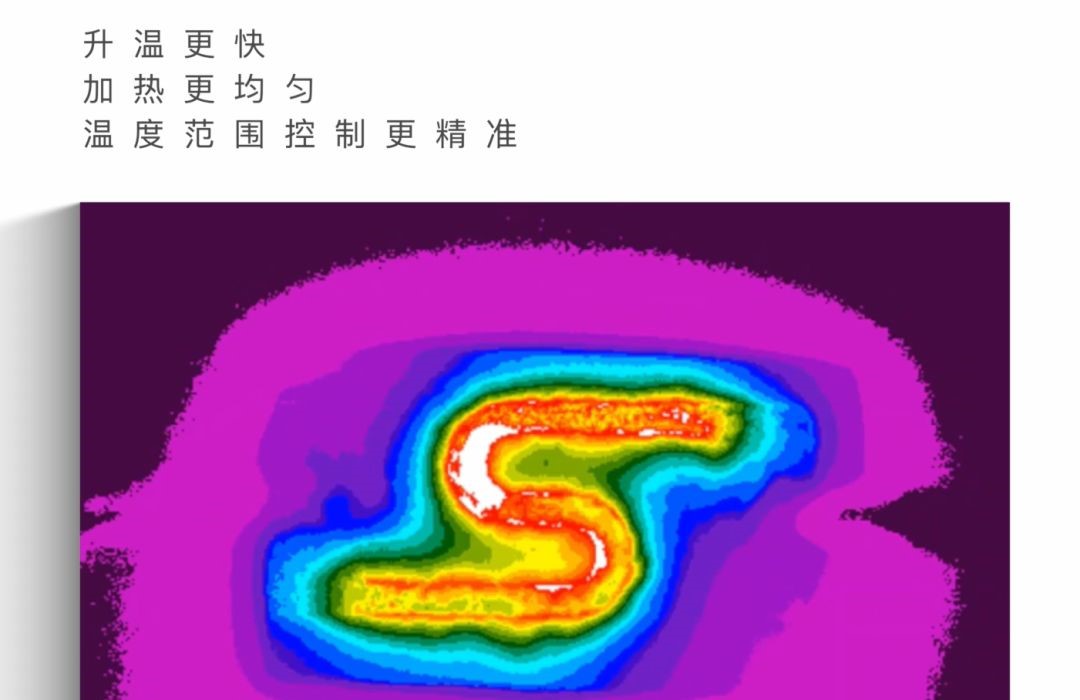

Similar to activated carbon, porous ceramic materials have strong adsorption properties and at the same time very good biocompatibility properties. This is one of the key factors in choosing ceramics as a carrier. Similar materials have many applications in daily life, such as filter cartridges for water purifiers, refrigerator deodorants, face masks, toothpaste and other daily necessities. Second, what are the advantages of ceramic atomising core? Compared with the atomising core composed of other materials, such as heating wire and fibre rope, heating wire and organic cotton, the ceramic atomising core is characterised by a faster rise in temperature, better temperature uniformity and more precise control of the temperature range during the heating process. This can reduce the production of aldehydes and ketones in the process of use to a greater extent, thus ensuring the safety of the use process.  The ceramic core consists of two parts: the ceramic is sintered at high temperature to make a bowl-like structure, and the heating film is designed to be attached to the surface of the ceramic in the form of an S-shape, and their relationship is just like a pot and a stove when cooking. As the core component of the atomiser, the atomising core heats up the liquid to form mist by uniform heating of the heating film during the working process.

The ceramic core consists of two parts: the ceramic is sintered at high temperature to make a bowl-like structure, and the heating film is designed to be attached to the surface of the ceramic in the form of an S-shape, and their relationship is just like a pot and a stove when cooking. As the core component of the atomiser, the atomising core heats up the liquid to form mist by uniform heating of the heating film during the working process.  The heating temperature of the atomiser core directly affects the vaping experience of the electronic atomiser. Ceramic atomiser core can effectively avoid local carbonation phenomenon through uniform heating, and combined with the liquid conductivity of ceramic, it can effectively reduce the "burnt smell", which is a pain point in the industry.

The heating temperature of the atomiser core directly affects the vaping experience of the electronic atomiser. Ceramic atomiser core can effectively avoid local carbonation phenomenon through uniform heating, and combined with the liquid conductivity of ceramic, it can effectively reduce the "burnt smell", which is a pain point in the industry.